Bienvenue chez Horizon Hobby Europe - achetez directement auprès du fabricant. Livraison à partir de l'entrepôt en Allemagne !

Sur commande

A5070 Mini Digital HV High Torque High-Speed Brushless Metal Gear Aircraft Servo

Item No.

SPMSA5070

Sur commande

A5070 Mini Digital HV High Torque High-Speed Brushless Metal Gear Aircraft Servo

Item No.

SPMSA5070

€ 169,99

Magasin sélectionné

Product Details

Spektrum high-voltage, brushless servos deliver dependable power and digital precision with amazing efficiency. Finely tuned electronics and software integrate with powerful brushless motor technology to offer ultra-smooth, high-speed performance more efficiently than servos with conventional motors. The all-aluminum case provides the ultimate solution in durability and heat dissipation, while precision metal gears complete a satisfaction package even the most critical pilot can appreciate. The Spektrum A5070 mini servo uses this solid foundation to achieve a whopping 190 oz/in of torque* and high transit speeds of .07 sec* in addition to its outstanding balance of durability, value, plus the peace-of-mind that sophisticated error correction and over-current/temperature protection offers. It’s an impressive feature combination that makes this mighty servo an outstanding airplane or heli servo choice.Key Features

- High torque both on HV and non-HV applications

- Allows BECs of adjustable BEC ESCs to be set higher to increase performance

- Acts as a heat sink for the motor and ESC

- Low deadband, high resolution, with impressive holding torque for unmatched performance

- Durable high performance finish

Liens utiles

Manuals & SupportProduct Specifications

| Programmable | No |

| Servo Size Category | Mini |

| Bearing | Dual Ball Bearing |

| Bushing Or Bearing | Bearing |

| Gear Type | Metal |

| Wire Gauge | 22 AWG |

| Motor Type | Brushless |

| Servo Operating Voltage | 6.0 - 8.4V (HV) |

| Application | Airplane or Heli |

| Overload Protection | Yes |

| Product Weight | 1.4 oz (40g) |

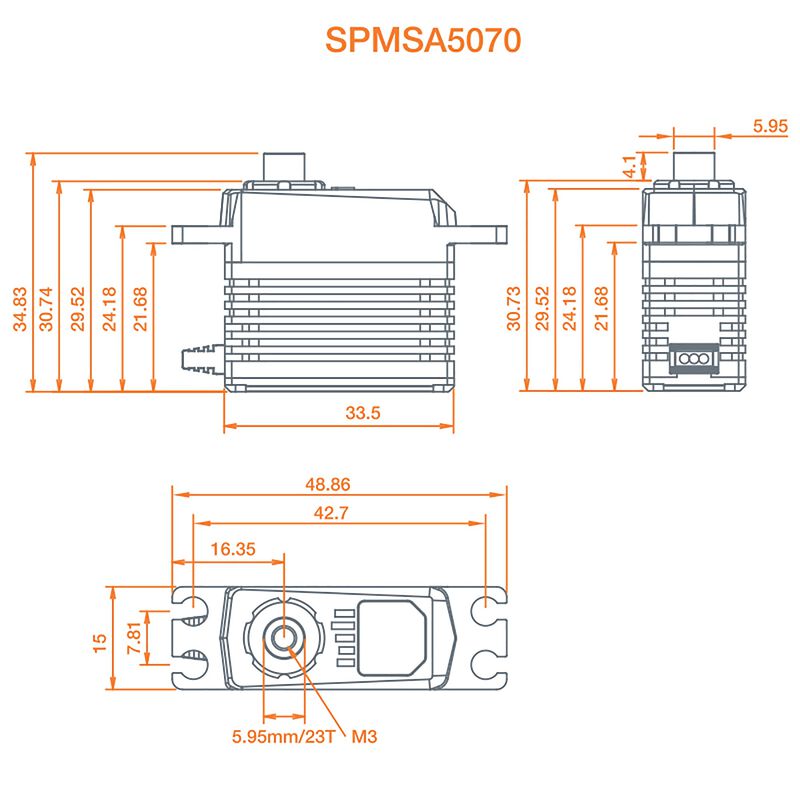

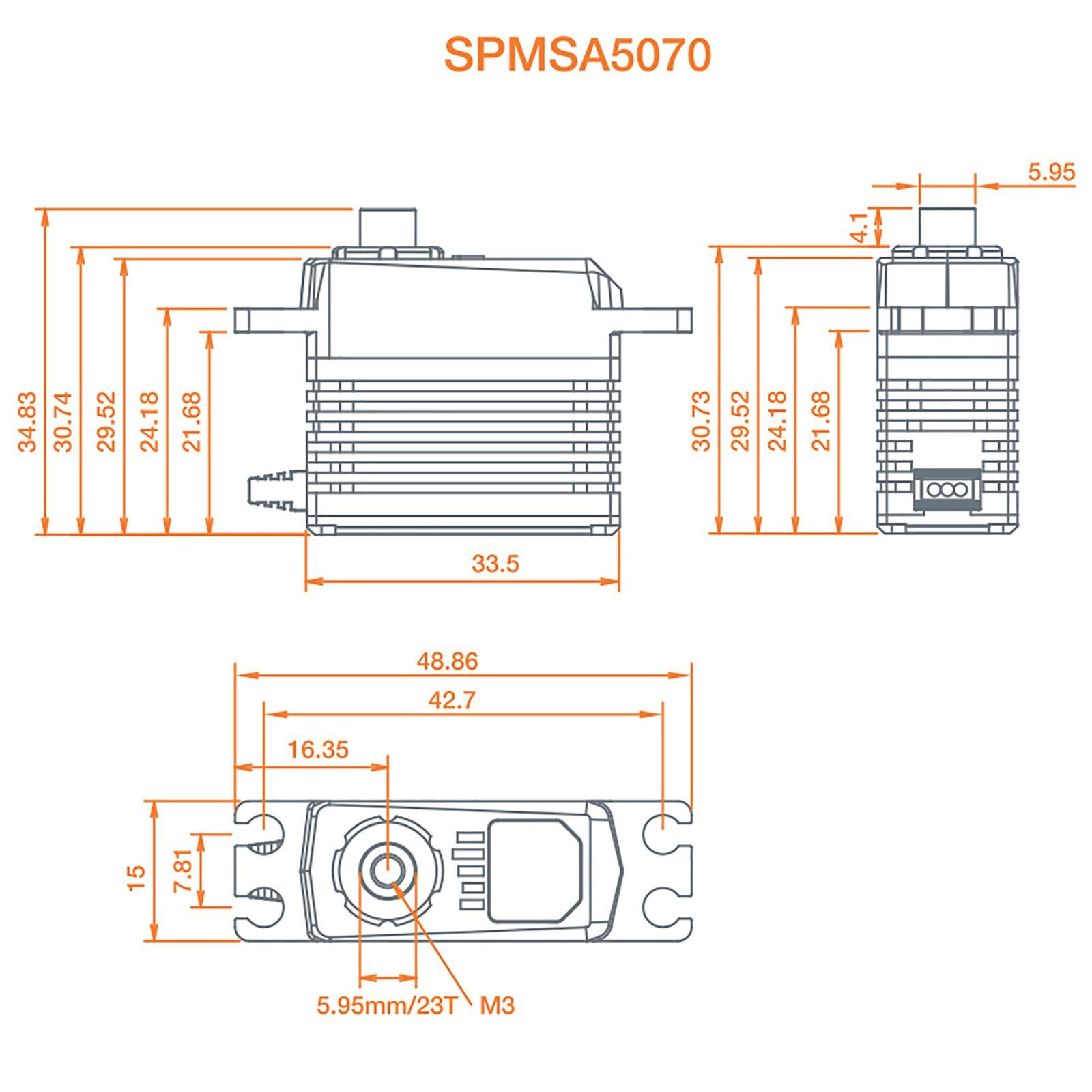

| Spline Count | 23 - Tooth |

| Water-Resistant | No |

| Deadband | 2µs |

| Product Application | Air |

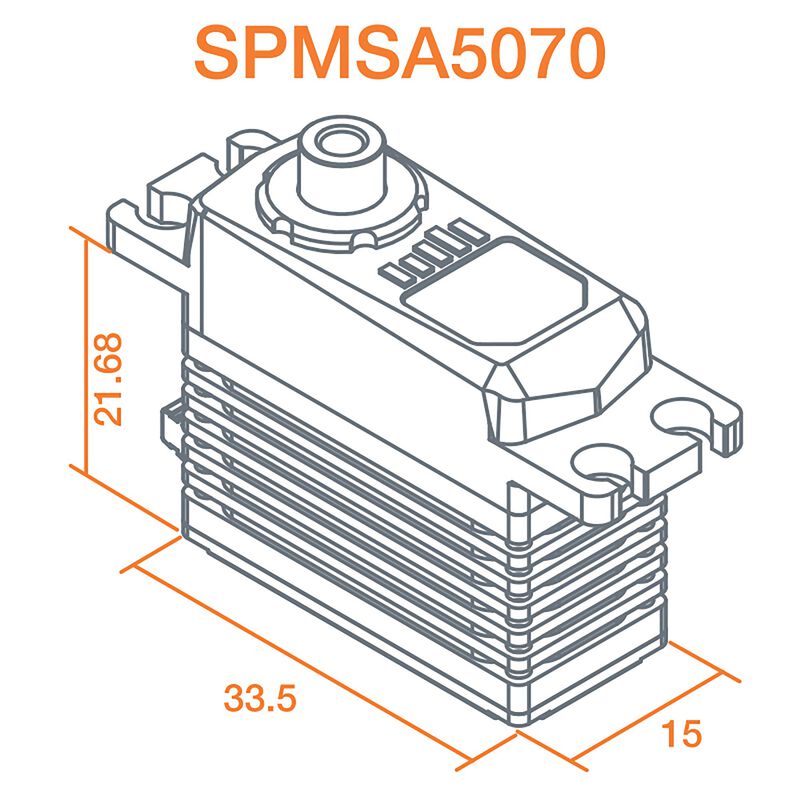

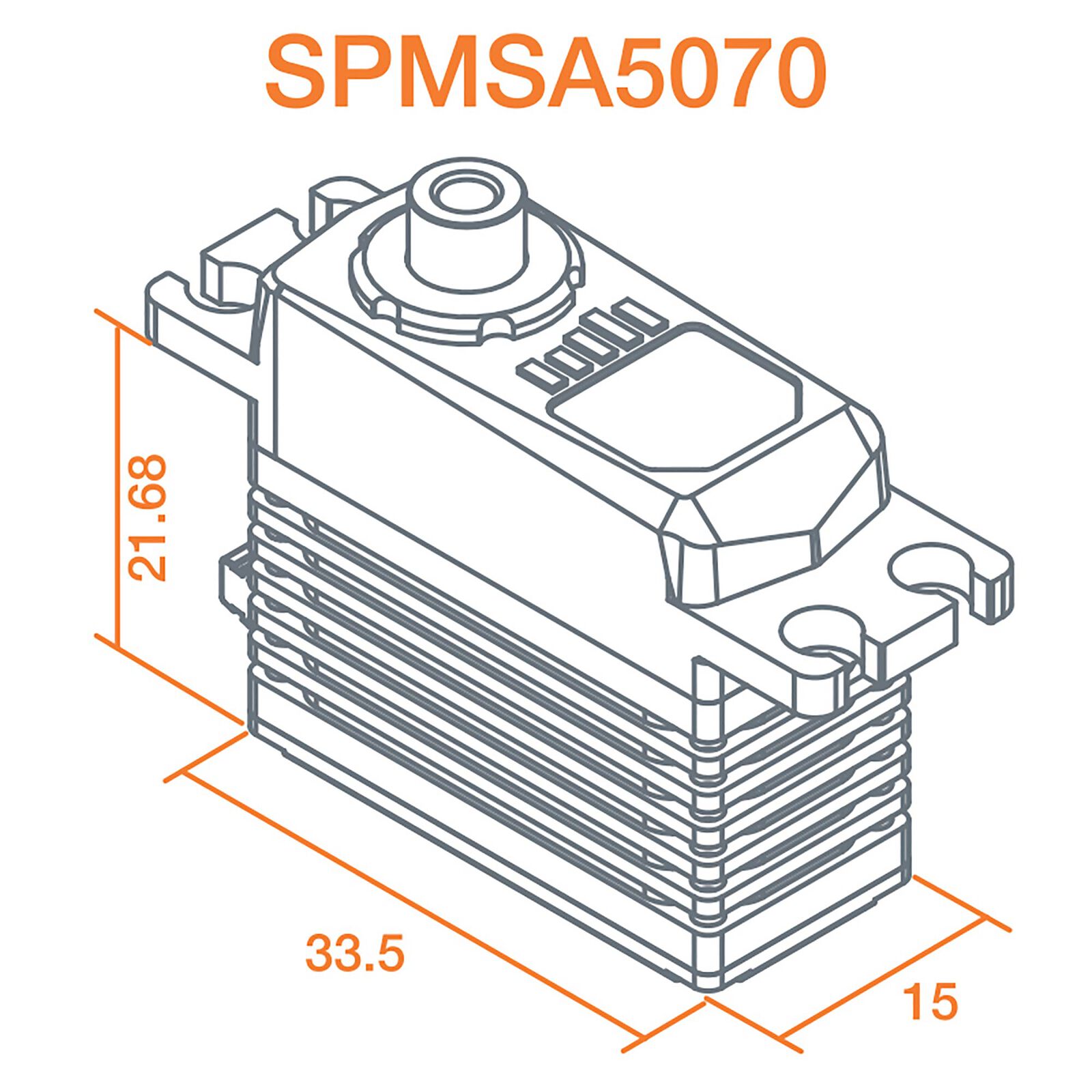

| Product Height | 1.16" (29 mm) |

| Servo Type | Digital |

| Connector Type | Universal |

| Maximum Servo Speed | 0.094 sec/60 deg @6.0V; 0.078 sec/60 deg @ 8.4V |

| Product Length | 1.32" (34 mm) |

| Rotation Range | 120 Degrees |

| Connector Wire Length | 11.8" (300 mm) |

| Product Width | 0.59" (15 mm) |

| Maximum Servo Torque | 146.43 oz-in @6.0V; 190.58 oz-in @ 8.4V |

Revendeurs

Revendeurs